Flare Gas Recovery Solutions

At Multronic AutoPower, we deliver end-to-end solutions for flare gas capturing and recovery, helping refineries minimize environmental impact and enhance energy efficiency. Our projects typically involve the following key activities:

- Conducting detailed data collection campaigns to measure gas flow, pressure, temperature, and composition

- Designing and installing Flare Gas Recovery Units (FGRUs) customized to each site

- Building pipeline and gas storage tanks for gas centralization

- Designing and building power plants that convert flare gas into electricity using gas-powered generators

Each phase is carefully engineered to ensure safety, sustainability, and optimal economic returns.

What we offer

Gas Storage Facility

Dedicated gas storage facility will be constructed to:

- Store the recovered gas safely.

- Regulate pressure levels.

- Ensure continuous gas supply for power generation.

The storage tank will comply with industry standards for safety, capacity, and operational efficiency.

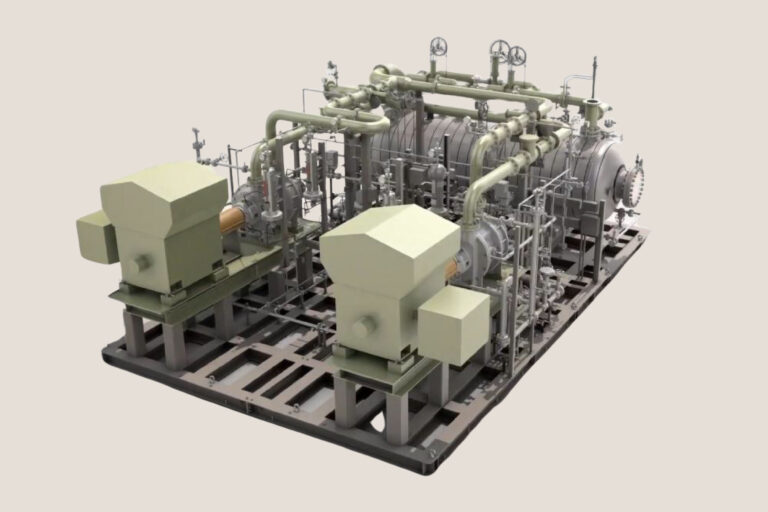

Flare Gas Recovery Unit (FGRU)

Based on collected data, a customized Flare Gas Recovery Unit (FGRU) will be designed and installed. This unit will:

- Capture and compress the flare gas.

- Remove impurities and moisture.

- Prepare the gas for centralized collection and further processing.

Measurement & Monitoring Activities

- Flow Rate Monitoring: precise gas flow measurement with an error margin below 1%. These measurement provide accurate real-time data and are suitable for varying gas compositions.

- Pressure Monitoring: Installation of pressure sensors, which provide high-accuracy digital pressure readings with built-in temperature compensation.

- Temperature Monitoring: Integrated within the thermal mass flow meter, eliminating the need for separate sensors. The system will capture real-time temperature data of the flare gas.

- Gas Composition Analysis: Sampling gas directly from the pipeline, analysed using a gas chromatograph to determine hydrocarbon composition.

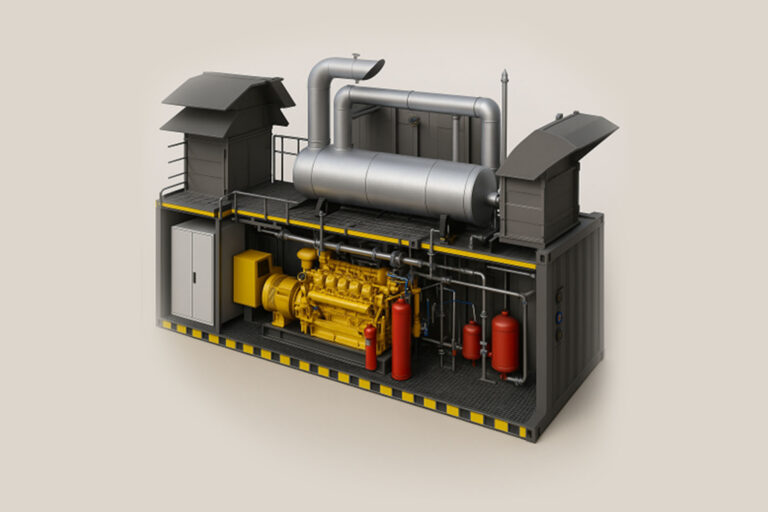

Gas-powered Generators

The power plant will be designed to utilize the stored gas for electricity generation. The plant will include:

- Gas-powered generators capable of converting flare gas into electricity.

- Emission control systems to ensure minimal environmental impact.

- A power distribution network to integrate the generated electricity into the grid or refinery operations.

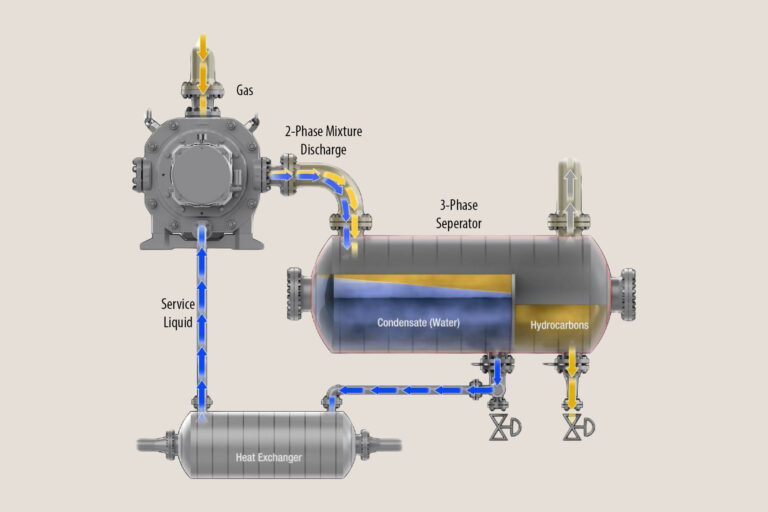

Three-Phase Seperation for Recovery of Hydrocarbons

This system efficiently separates well fluids into three distinct phases: oil (hydrocarbons), water, and gas. Utilizing gravity and advanced separation techniques, it maximizes the recovery of valuable hydrocarbons while effectively separating water and gas for further processing or disposal. This technology enhances operational efficiency and contributes to optimized resource management in the petroleum industry.